China wholesale Steel Structure Leather Factory - China cheap prefab metal frame light prefabricated steel warehouse Structure workshop building factory shed construction drawing – Xinguangzheng Detail:

| Items | Specification | |

| Main Steel Frame | Column | Q235B, Q345B Welded H Section Steel |

| Beam | Q235B, Q345B Welded H Section Steel | |

| Secondary Frame | Purlin | Q235B C or Z purlin |

| Knee brace | Q235B Angle Steel | |

| Tie Rod | Q235B Steel Pipe | |

| Brace | Q235B Round Bar | |

| Vertical and Horizontal Support | Q235B Angle Steel, Round Bar or Steel Pipe | |

| Maintenance system | Roof | EPS Sandwich Panel / Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / PU Sandwich Panel / Corrugated Steel Sheet |

| Wall | EPS Sandwich Panel / Glass Fiber Sandwich Panel / Rock Wool Sandwich Panel / PU Sandwich Panel / Corrugated Steel Sheet / Glass curtain wall / Aluminum composite panel | |

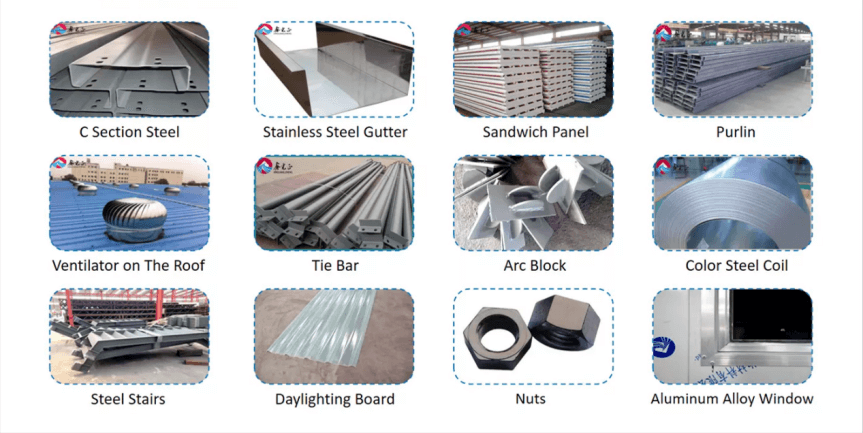

| Accessories | Window | Aluminium Alloy Window / PVC Window |

| Door | Sliding Sandwich Panel Door / Roll-up Door / Lifting Door / PVC Fast Door / Entrance Door | |

| Rainspout | PVC / UPVC | |

| Live load on Roof | In 120 kg / Sq.m (Color steel panel surrounded) | |

| Wind Resistance Grade | as per local data | |

| Earthquake-resistance | as per local data | |

| Structure Usage | Up to 50 years | |

| Finishing | Optional | |

| Paint Options | Alkyd anti-rust paint / Zinc rich epoxy paint / Hot dipped galvanized | |

Building Options & Specifications

1. Options

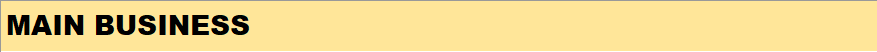

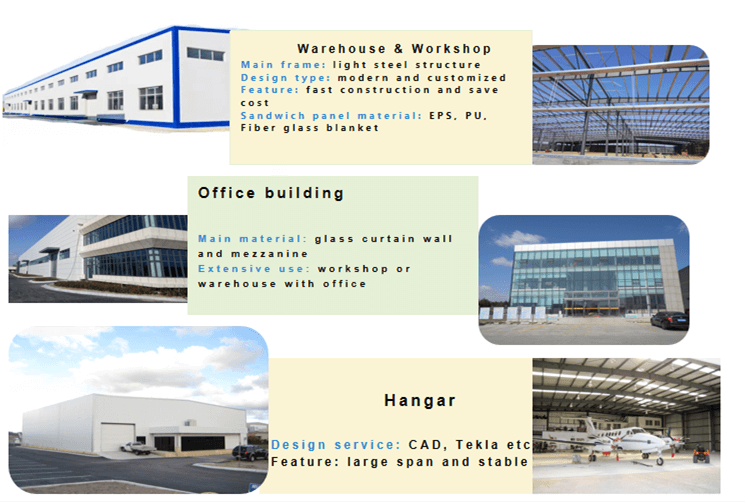

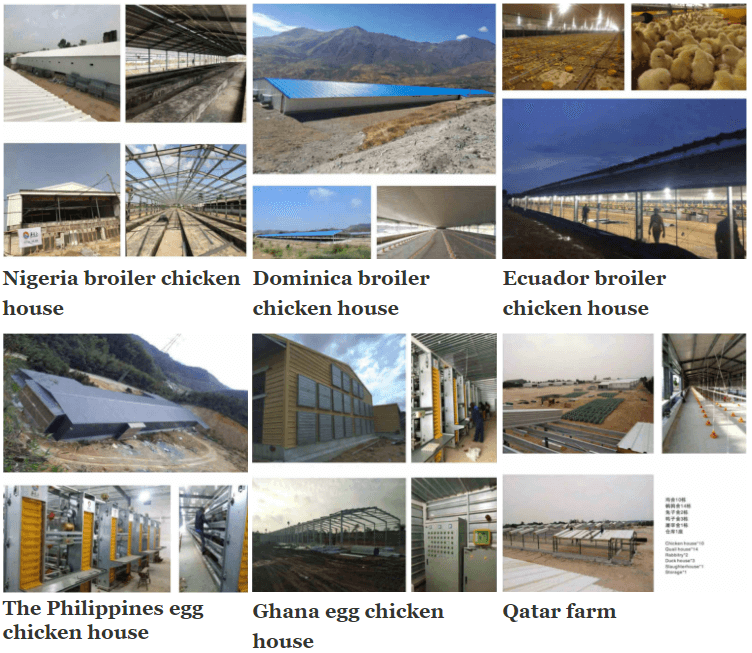

1)We can supply steel structures building for workshop,warehouse,hangar,hotel,apartment,shopping mall,container house, poultry house, modular house, garage, bridge crane, various steel structure materials etc.

2)We can also make and develop new parts according to customers’ drawings and detailed dimensions.

2.Specifications

1) Size(m):

Width * Length * Eave Height;

2)Type:

Single slope, double slope, Multi-slope;

Single span, double-span, Multi-span;

Single floor, double floors,Multi-floors;

3) Base: steel foundation bolts

4) Steel fream:

Material Q345(S355JR)(Gr50)or Q235(S235JR) steel;

All bolts connection;

Straight cross-section or Variable cross-section;

5) Bracing: X-type or V-type or other type bracing made from angle, round bar, etc ;

6) Wall & Roof C/Z Purlin: Size from C80~C300; Z100~Z300;

7) Roof and wall panel:

Single color corrugated steel sheet 0.5mm thick;

Sandwich panel with EPS, ROCK WOOL, PU etc insulation, thickness around 50mm~200mm;

8)Window:UPVC or Aluminum Alloy.

9)Door:Sliding or Roller shutter door.

10) Gutter material:Color steel sheet or galvanized steel or stainless steel;

11)Rainspout: UPVC pipe

12)Accessories: Skylight panel, Ventilation, Fasteners etc

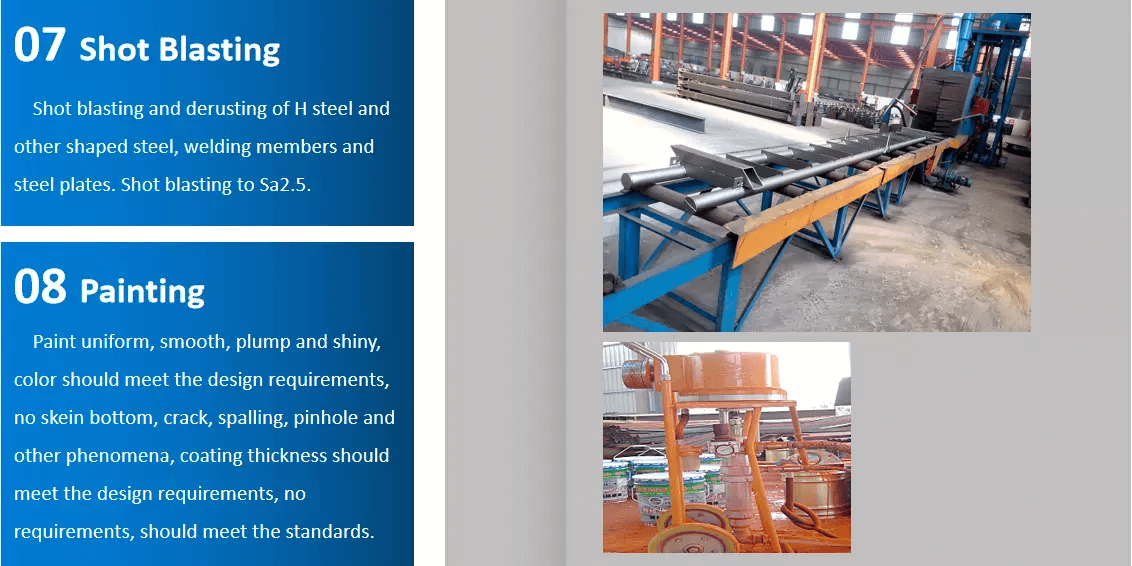

13)Surface process: Shot blasting Sa2.5;Two lays of Anti-rust Painting!

14) Packing: Main steel frame without packing load in 40′ OT, roof and wall panel load in 40′ HQ!

Advantages of steel structure building than concrete structure:

1. The total weight of the building is light: about half of the concrete structure weight, which can reduce the foundation cost

2. Fast construction: the construction period is shortened by 1/4 to 1/6 compared with the traditional concrete structure

3. Strong flexibility: large open span design, indoor space can be divided into multiple programs to meet the different needs of owners. In particular, the exhibition center can adopt the pipe truss structure, which is easy to realize the large space function, increase the space height, and has the characteristics of beauty and comfort. This structure has been mostly used in airport projects.

4. Good energy-saving effect: the wall is made of factory-made steel components, or light-weight energy-saving standardized C-shaped steel, square steel, sandwich panel, high processing precision, good thermal insulation performance, good earthquake resistance

5. Good environmental protection effect: greatly reduce the amount of sand, stone, ash, environmental protection and energy saving during construction.

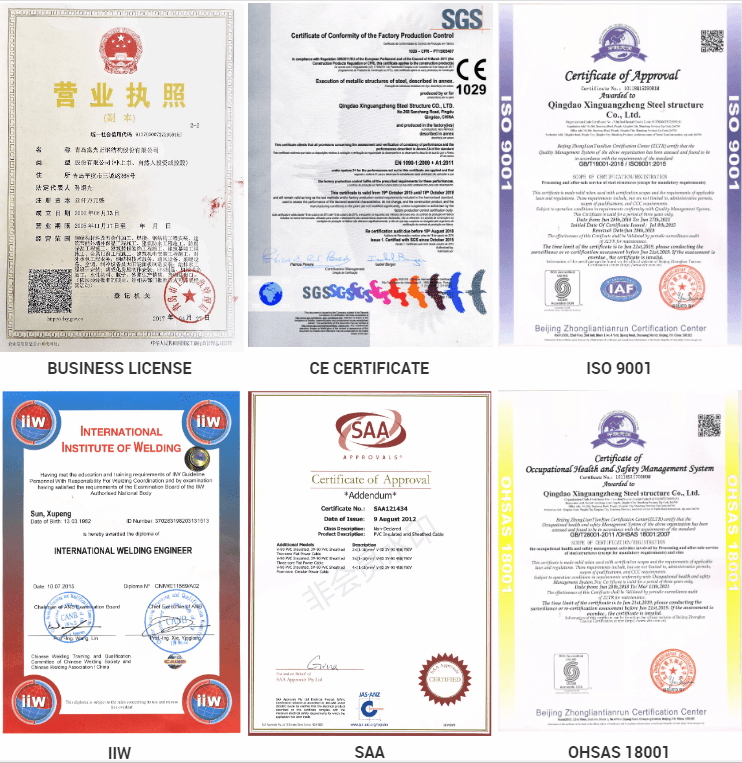

All of our products have already been authorized through ISO9001 quality system. We have specialized quality control departments. We also have a very strict quality control system to the products. Because we want to be responsible for every product quality we sold. Our group company has set up a very good reputation for many years. We will offer the products resting assured to customer.

Why choose our prefabricated steel structure building?

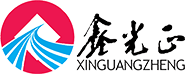

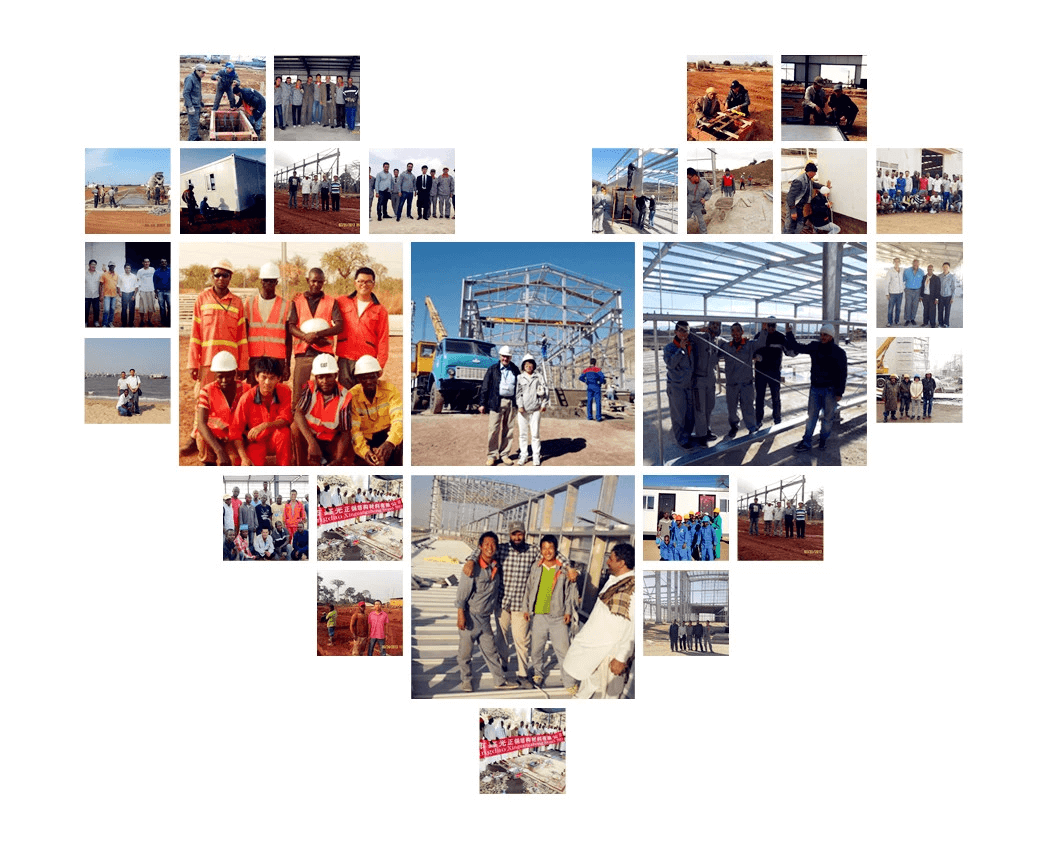

1. More than 22 years’ experience, our products had been exported to more than 80 countries all over the world.

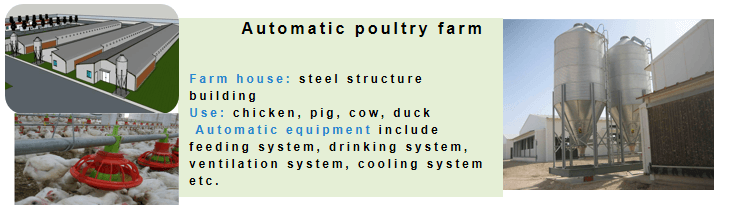

2. We supply R & D, engineering, fabrication, exporting, and installation with one stop shopping service.

3. With ISO9001:2015, SGS, BV and CE certification

4. Xinguangzheng group with 5 branch factories located in Qingdao, Shandong Province. Our annual production capacity: only for H welded steel: 720,000 TONS – 1,200,000 TONS per year

5. Design software: PKPM, 3D3S, X-Steel, SAP2000, AUTOCAD, T-Arch, etc

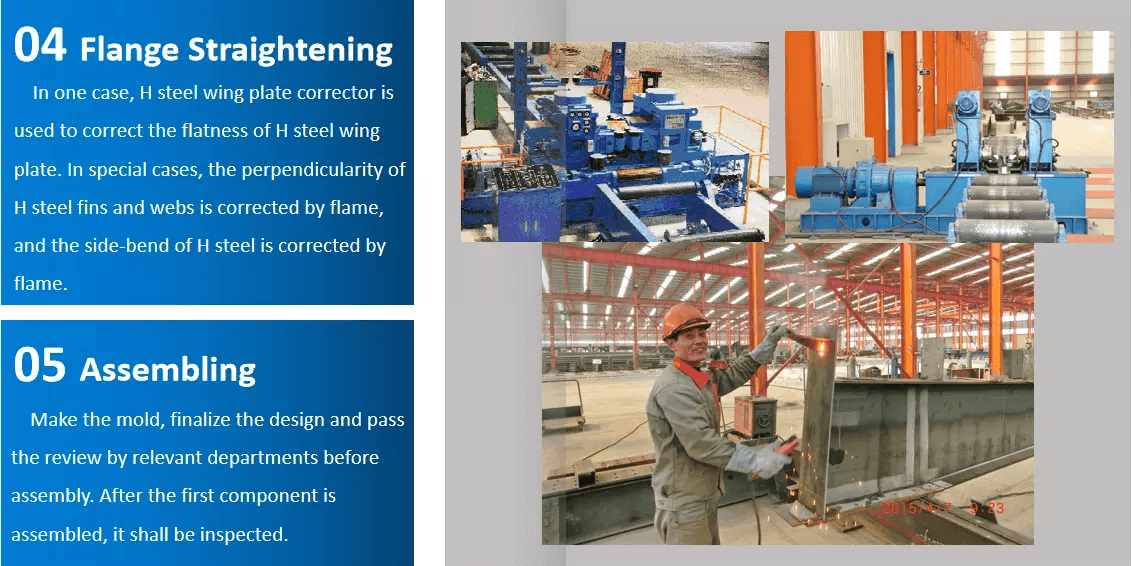

Product detail pictures:

Related Product Guide:

Steel structure showroom in Manaus Brazil

A type Chicken Cage VS H type Chicken cage

We believe that long time period partnership is a result of top of the range, value added services, rich expertise and personal contact for China wholesale Steel Structure Leather Factory - China cheap prefab metal frame light prefabricated steel warehouse Structure workshop building factory shed construction drawing – Xinguangzheng, The product will supply to all over the world, such as: Indonesia, Malaysia, Portugal, Now we have a dedicated and aggressive sales team, and many branches, catering to our main customers. We have been looking for long-term business partnerships, and ensure our suppliers that they will undoubtedly benefit in both short and long run.

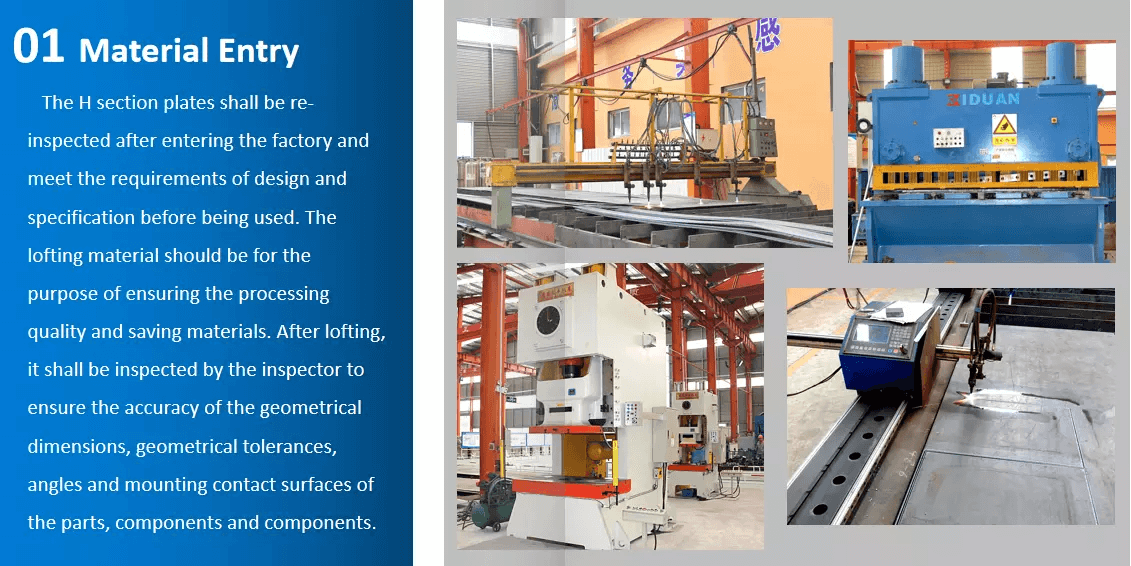

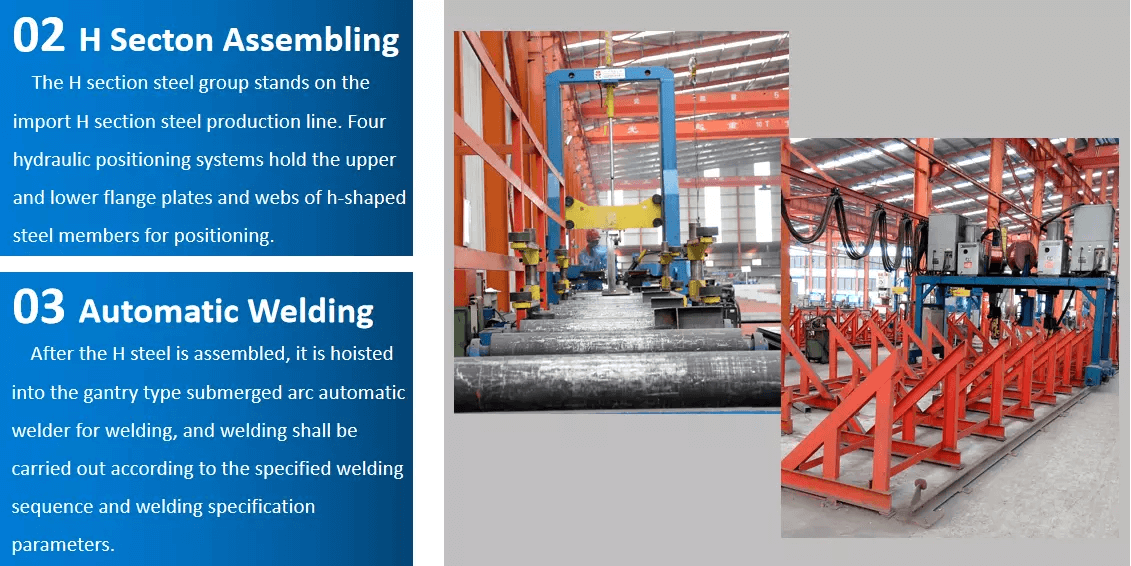

We put much fund in introducing advanced production lines of sandwich panels, corrugated steel sheets, H section steel, C/Z section steel, EPS foam board and EPS packing machines. Our company has well-trained processing teams, advanced technical equipment, professional quality inspection teams and mature management policies in each link, which can effectively ensure the quality of products, but also an important factor to reduce the cost of our products.

Our factory is a professional steel structure manufacturer in China. We are capable in taking over all types of steel structure building, such as steel structure warehouse, steel structure workshop, poultry house and so on, which contains all step of designing, producing, installing.

Our factory was founded in 1997, our products have been exported to more than 80 countries all over the world. Besides, we have strong engineering teams of 60 senior engineers.

We are a group factory of 5 branch factories and we can produce all accessory materials of steel buildings by ourselves.

Q: You are manufacture factory or trading company?

A: We are manufacture factory. And you are welcomed to visit us at any time.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shipment.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to

quantity.

Q: Do you offer designing service for us?

A: Yes, we could design full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (X steel) and etc. We can design complex industrial building like office mansion, supermarket, auto dealer shop, shipping mall,

hotel.

Q: Can you provide the installation help?

A: We will provide detailed instruction photos and videos to you. If it is necessary, we will send professional engineers to do the construction guidance, and some skilled workers to help installation.