Factory wholesale Chicken Farming Automatic Equipment - Hot sale poultry farming house and equipment poultry feed machine – Xinguangzheng Detail:

Hot sale poultry farming house and equipment poultry feed machine

| product name | China manufacture steel poultry house poultry farm building equipment |

| material grade | Q345B / Q235B |

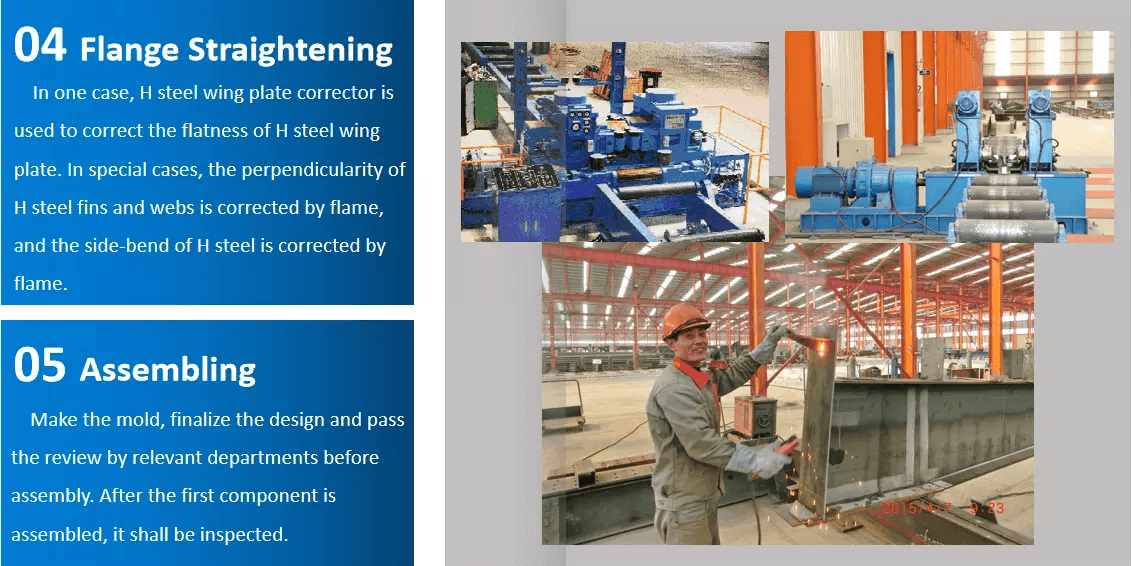

| surface treatment | Galvanized |

| building size | Customer required |

| roof and wall | Galvanized steel sheet metal |

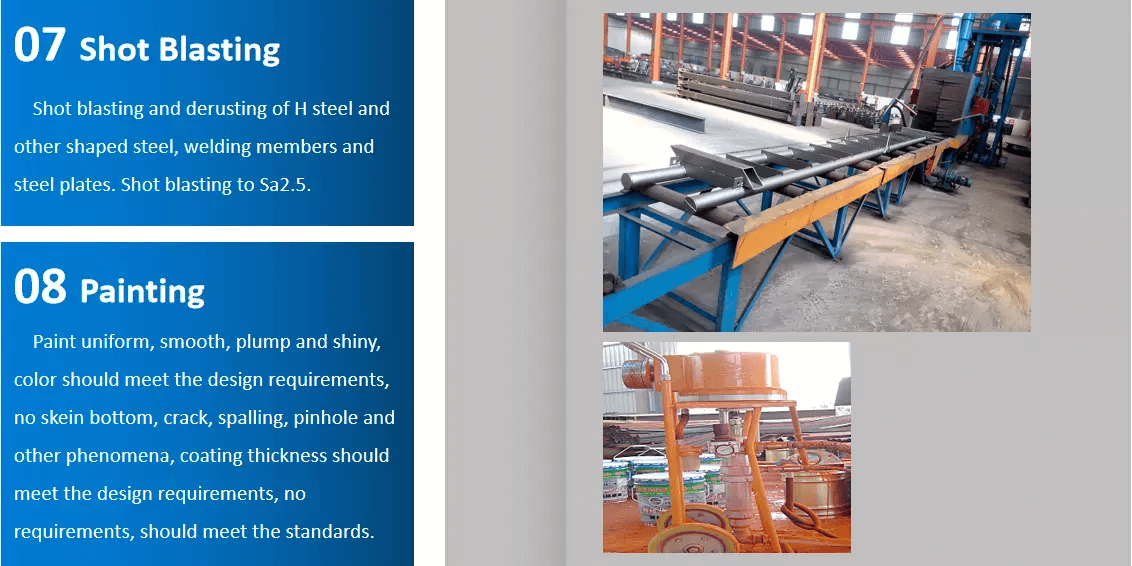

| insulation material | Fiber glass wool insulation |

| usage | Chicken house |

| equipment | Full automatic feeding equipment |

| feeding type | Cages feeding or floor feeding |

| brand name | XGZ |

| building life time | 50 years |

| place of origin | Shandong, China |

Product description:

Project name: Angola poultry farm project

Location: Angola

Project time: 2010

Total Area:12,000 sqm

Unit area of chicken cage:12m×63m

Unit area of layer house :12m×93m

Unit area of broiler house:14m×102m

Material Requirements: Light steel keel, EPS sandwich panel roof and wall system, to meet the requirements of low cost and thermal insulation.

Why choose our chicken house?

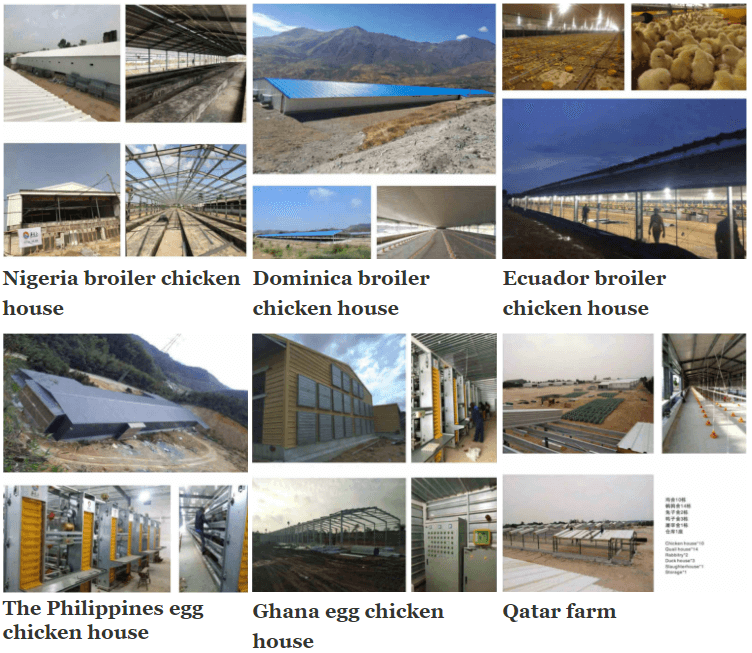

1. More than 24 years’ experience, our products had been exported to more than 80 countries all over the world

2. We supply R & D, engineering, fabrication, exporting, and installation with one stop shopping service.

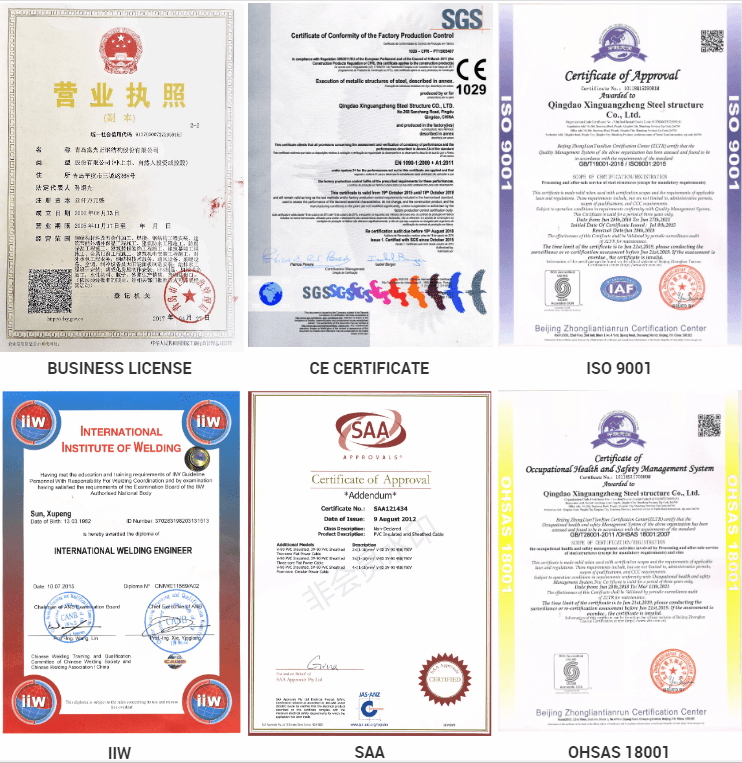

3. With ISO9001:2015, SGS, BV and CE certification

4. Xinguangzheng group with 5 branch factories located in Qingdao, Shandong Province. Our annual production capacity: only for H welded steel: 720,000 TONS – 1,200,000 TONS per year

5. Design software: PKPM, 3D3S, X-Steel, SAP2000, AUTOCAD, T-Arch, etc

Chicken House Characteristics:

1. rust protection, acid resistance, good insulation performance.

2. simple structure, high efficiency, lower cost, great flexibility.

3. It has a good performance of wind resistant, earthquake resistant, lighting protection and environment friendly.

The size range:

1. chicken house width: 12m-15m

2. length: not longer than 150m

3. the height: 2.2m-4m

4. Reasonable feeding qty: 13-15 chickens per square meter

For an example, we will raise 20,000 chickens.

Building size is L 135 m x W 15 m x H 2.5 m

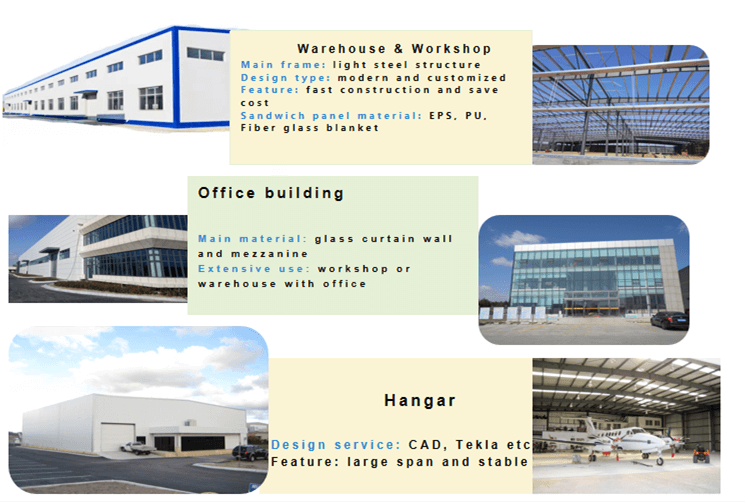

Chicken House Fully Automatic equipments list:

1.Main feed line system

2.Pan feeding system

3.Nipple drinking system

4.Ventilation system

5.Cooling pad system

6.Spraying system

7.Heating system

8.Environment control system

Environment control:

Cooling pad system

Evaporative cooling pad system works in the condition of negative pressure, the cooling pad has been installed in one side of the wall, the fans has been installed in the other side of the wall. When the air flows through the cooling pads, the water evaporation absorbs a lot amount of heat.

Normally the height of cooling pad is 1.5 m - 2.2 m, length is about 3 m, the area of cooling pad in chicken house is about 6-8 times than the fans.

Ventilation system

The main parts of ventilation system is the big fan and the small fan. They are controlled by the control system. The running qty of the fans was depended on the required temperature of the poultry house.

Normally, for about 200m2 area, it needs 1 big fan and 15-20m need a small fan, this is the standard to design the quantity of fans in the chicken house.

“H” type automated feeding equipments for layers ( type 5300 )

| Product name | “H” type egg laying chicken cage |

| Material | Galvanized wire |

| Tiers | 3/4/5/6/8 ties |

| Capacity | 180/240/300/360/544 |

| Cage size | 2285mm x 600mm x 430mm |

| Area/chicken | 450cm2 / 494cm2 |

| Product name | “H” type egg laying chicken cage |

| Material | Galvanized wire |

| Tiers | 4 Tiers |

| Capacity | 240 |

| Cage size | 1200mm x 650mm x 425mm |

| Area/chicken | 390cm2 |

| Product name | “H” type egg laying chicken cage |

| Material | Galvanized wire |

| Tiers | 4 tiers |

| Capacity | 240 |

| Cage size | 2250 mm x 650mm x 430mm |

| Area/Chicken | 450cm2 |

“A” type layer cage ALD-4160, ALD-4128

| Product name | A type layer chicken cages |

| Material | Hot-dipped zinc steel or spray |

| Tiers | 3/4 tiers |

| Capacity | 96/150/160/128 chickens per set |

| Cage size | 1870mm x 370mm x 370mm-315mm1840mm x 500mm x 400mm |

| Area/chicken | 432 cm2 / 450 cm2 |

Features:

1. Automated controlled system;

2. High rearing efficiency;

3. Designed for rearing and growing;

4. Floor saving and cost efficient;

5. Easy maintenance and operation

Detail product:

Material: Low carbon steel wire

Surface treatment: Electro galvanize or hot galvanize, Specialty: Easy to assemble. Feeding and easy management, save the space, effectively prevent infectious diseases, and increase the survival rate

Scalability: can be adjusted according to the size, can add automatic drinking water system, also available for one layer or layers adjustment.

If there are some special specifications, also can be customized to sample.

All of our products have already been authorized through ISO9001 quality system. We have specialized quality control departments. We also have a very strict quality control system to the products. Because we want to be responsible for every product quality we sold. Our group company has set up a very good reputation for many years. We will offer the products resting assured to customer.

2. Chicken equipment

Layer cage equipment

Automatic pan and nipple feeding line system

Performance parameters of feeding line system

(1) High-quality special driving reduction motor.

(2) V-shaped Bin (with hopper)

Bin volume: 115L, hopper volume :38L

Material: hot-dip galvanized sheet.

Nipple feeding line system

It can provide fresh and clean water for poultry which is crucial for the growth of Poultry.

The drinkers can be triggered from 360 degree which helps young birds start well and makes drinking more easily.

Product detail pictures:

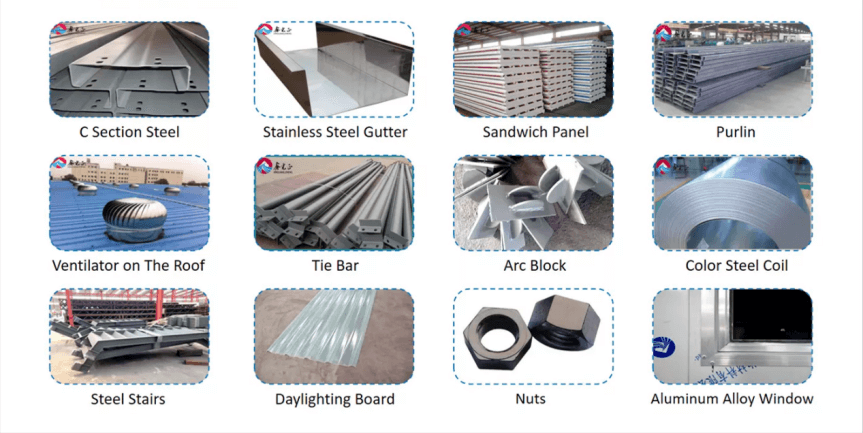

Related Product Guide:

Steel structure showroom in Manaus Brazil

Costa Rica Steel Structure Super Market

With this motto in mind, we've got develop into amongst one of the most technologically innovative, cost-efficient, and price-competitive manufacturers for Factory wholesale Chicken Farming Automatic Equipment - Hot sale poultry farming house and equipment poultry feed machine – Xinguangzheng, The product will supply to all over the world, such as: Kyrgyzstan, Congo, Hungary, Our company has always insisted on the business principle of "Quality, Honest, and Customer First" by which we have won the trust of clients both from at home and abroad. If you are interested in our solutions, you should do not hesitate to contact us for further information.

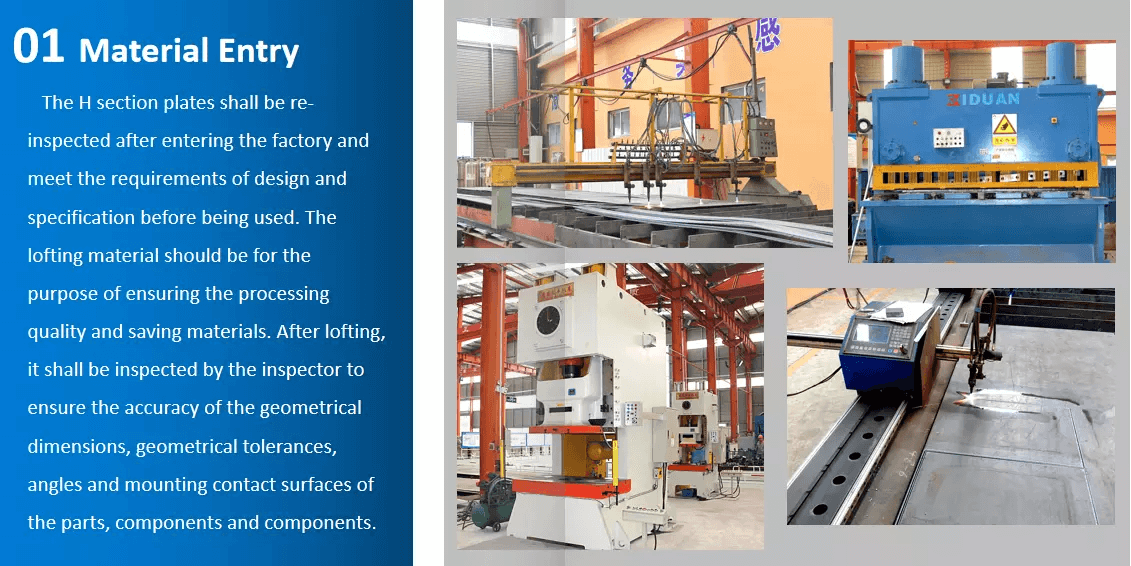

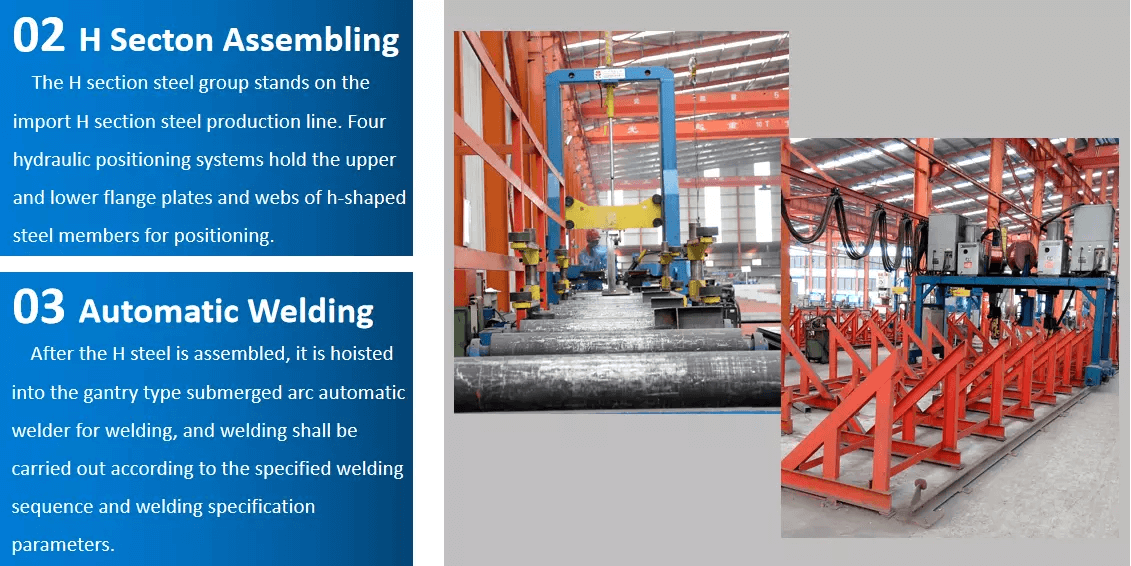

We put much fund in introducing advanced production lines of sandwich panels, corrugated steel sheets, H section steel, C/Z section steel, EPS foam board and EPS packing machines. Our company has well-trained processing teams, advanced technical equipment, professional quality inspection teams and mature management policies in each link, which can effectively ensure the quality of products, but also an important factor to reduce the cost of our products.

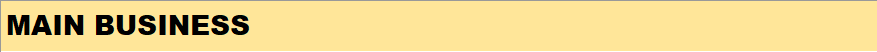

Our factory is a professional steel structure manufacturer in China. We are capable in taking over all types of steel structure building, such as steel structure warehouse, steel structure workshop, poultry house and so on, which contains all step of designing, producing, installing.

Our factory was founded in 1997, our products have been exported to more than 80 countries all over the world. Besides, we have strong engineering teams of 60 senior engineers.

We are a group factory of 5 branch factories and we can produce all accessory materials of steel buildings by ourselves.

Q: You are manufacture factory or trading company?

A: We are manufacture factory. And you are welcomed to visit us at any time.

Q: Do you provide samples ? Is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 30% T/T in advance , balance before shipment.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. Or it is 15-20 days if the goods are not in stock, it is according to

quantity.

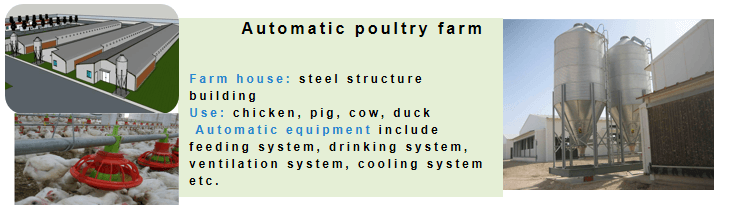

Q: Do you offer designing service for us?

A: Yes, we could design full solution drawings as your requirements. By using AutoCAD, PKPM, MTS, 3D3S, Tarch, Tekla Structures (X steel) and etc. We can design complex industrial building like office mansion, supermarket, auto dealer shop, shipping mall,

hotel.

Q: Can you provide the installation help?

A: We will provide detailed instruction photos and videos to you. If it is necessary, we will send professional engineers to do the construction guidance, and some skilled workers to help installation.